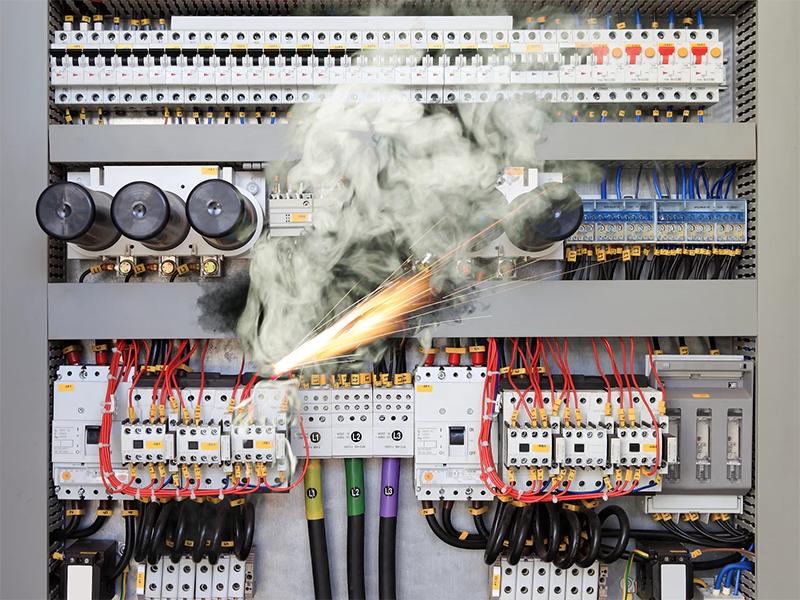

In the demanding environment of industrial operations, electrical surges pose a significant threat to sensitive equipment and critical processes. Unlike residential settings, industrial facilities often deal with high-voltage machinery, complex control systems, and extensive wiring networks, making them particularly vulnerable to transient voltage spikes. These surges can originate from various sources, including lightning strikes, power grid fluctuations, and the operation of heavy machinery within the facility itself. Implementing robust surge protection is not just a best practice; it’s a necessity for ensuring operational continuity and preventing costly downtime. The impact of electrical surges on industrial equipment can be devastating. Even seemingly minor voltage spikes can degrade sensitive electronic components over time, leading to premature failure and unexpected downtime. In critical systems, such as programmable logic controllers (PLCs), variable frequency drives (VFDs), and sophisticated sensor networks, a surge can result in data corruption, process interruptions, and even complete system shutdowns. The financial implications of such disruptions can be substantial, encompassing repair costs, lost production, and potential safety hazards. Effective surge protection in industrial settings requires a multi-layered approach. This involves installing surge protective devices (SPDs) at various points throughout the electrical distribution system, starting at the main service entrance and extending to individual equipment panels and critical devices. SPDs work by diverting excess voltage away from sensitive components, dissipating the surge safely to ground. Selecting the appropriate SPDs for specific applications is crucial, considering factors such as voltage rating, surge current capacity, and installation location. A comprehensive surge protection strategy should also include grounding and bonding practices to ensure a low-impedance path for surge currents. Beyond protecting equipment, surge protection plays a vital role in maintaining the reliability and longevity of industrial control systems. By minimizing the risk of voltage transients, businesses can reduce maintenance costs, extend the lifespan of their assets, and improve overall operational efficiency. Furthermore, surge protection contributes to a safer working environment by reducing the potential for electrical fires and equipment malfunctions caused by surge-related damage. In conclusion, investing in robust surge protection is an essential component of any well-designed industrial electrical system. By implementing a comprehensive strategy that includes properly selected SPDs and sound grounding practices, businesses can safeguard their valuable assets, minimize downtime, and ensure the continuous and reliable operation of their critical processes. In an era of increasing automation and reliance on sensitive electronic equipment, surge protection is not a luxury, but a fundamental requirement for industrial success.

The Importance of Surge Protection in Industrial Settings

Industrial settings require robust surge protection to prevent costly equipment damage, downtime, and safety hazards from electrical surges.