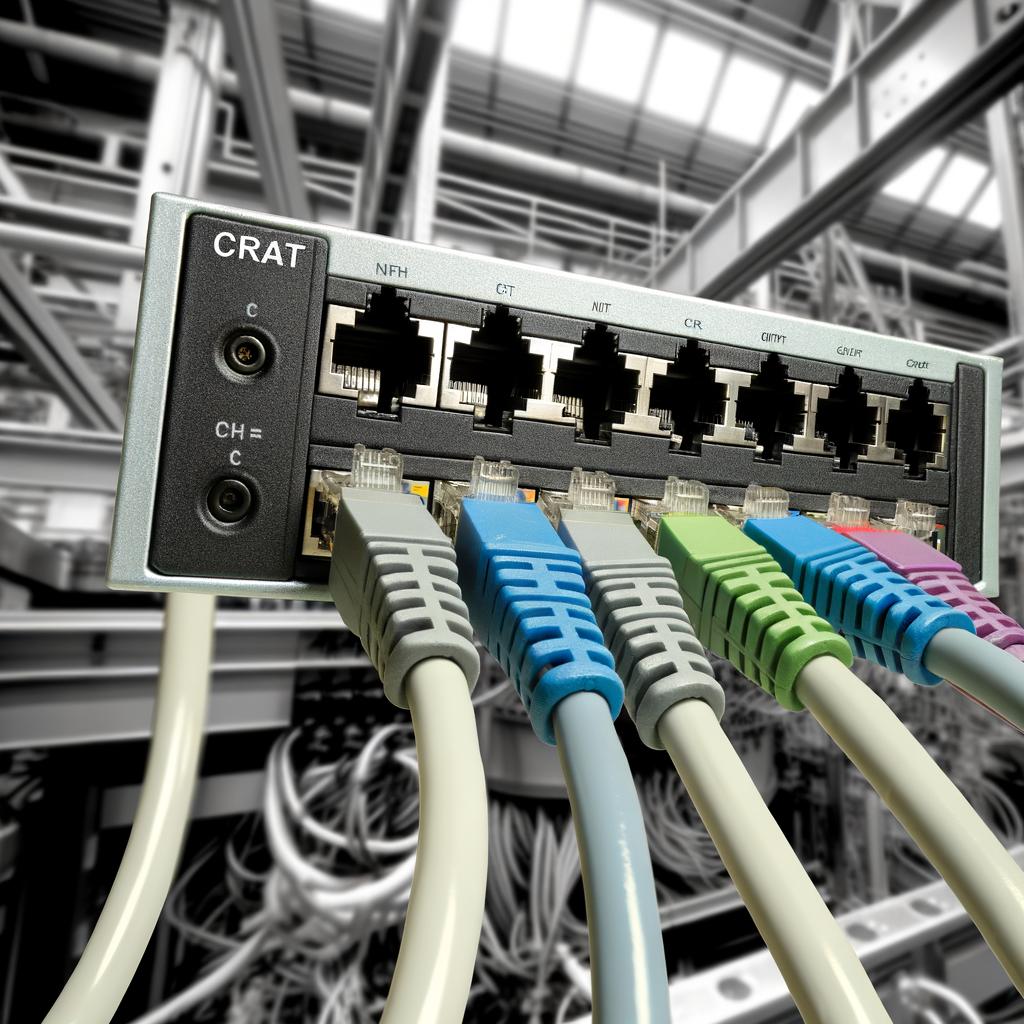

Connecting the Factory Floor: Unleashing the Power of Ethernet Switches in Industrial Settings In the ever-evolving landscape of industrial automation, seamless communication and data exchange are paramount. Ethernet switches have emerged as indispensable tools, revolutionizing how industrial networks operate and delivering a multitude of benefits that drive efficiency, reliability, and productivity. Unlike traditional hubs, which broadcast data to all connected devices, switches intelligently direct traffic, significantly enhancing network performance and reducing congestion. One of the most significant advantages of Ethernet switches in industrial settings is their ability to provide deterministic communication. This is crucial for real-time control applications, where precise timing and data delivery are essential. Switches prioritize critical data packets, ensuring timely delivery and minimizing latency. This deterministic behavior is vital for applications like motion control, robotics, and process automation, where even slight delays can lead to production errors or equipment damage. Industrial Ethernet switches offer enhanced network reliability and redundancy. Features like redundant ring topologies and link aggregation provide failover capabilities, ensuring continuous operation even in the event of a network failure. These features are particularly important in critical applications where downtime is unacceptable. Ruggedized designs, with extended temperature ranges and vibration resistance, further contribute to the reliability of these switches in harsh industrial environments. Security is another critical consideration in industrial networks. Ethernet switches offer advanced security features, such as VLANs (Virtual Local Area Networks) and access control lists (ACLs), which segment the network and restrict access to sensitive data and devices. This helps protect against unauthorized access and cyberattacks, which can have devastating consequences in industrial settings. Implementing secure network architectures is essential for safeguarding critical infrastructure and intellectual property. Ethernet switches also provide valuable diagnostic and management capabilities. Features like SNMP (Simple Network Management Protocol) and web-based interfaces allow for remote monitoring and troubleshooting, reducing the need for on-site personnel. This simplifies network management and enables proactive maintenance, minimizing downtime and improving overall network efficiency. Real-time monitoring of network traffic and device status provides valuable insights into network performance and helps identify potential bottlenecks or failures. The flexibility and scalability of Ethernet switches make them ideal for adapting to the evolving needs of industrial environments. They support a wide range of protocols and devices, enabling seamless integration with existing automation systems. As industrial facilities expand or upgrade, Ethernet switches can easily accommodate new devices and applications. This adaptability ensures that industrial networks can keep pace with technological advancements and changing business requirements. By leveraging the power of Ethernet switches, industrial facilities can achieve greater efficiency, reliability, and security, paving the way for a more connected and productive future.

The Benefits of Using Ethernet Switches in Industrial Settings

Ethernet switches in industrial settings enhance communication, reliability, security, and management through deterministic communication, redundancy, advanced security features, and remote monitoring capabilities.