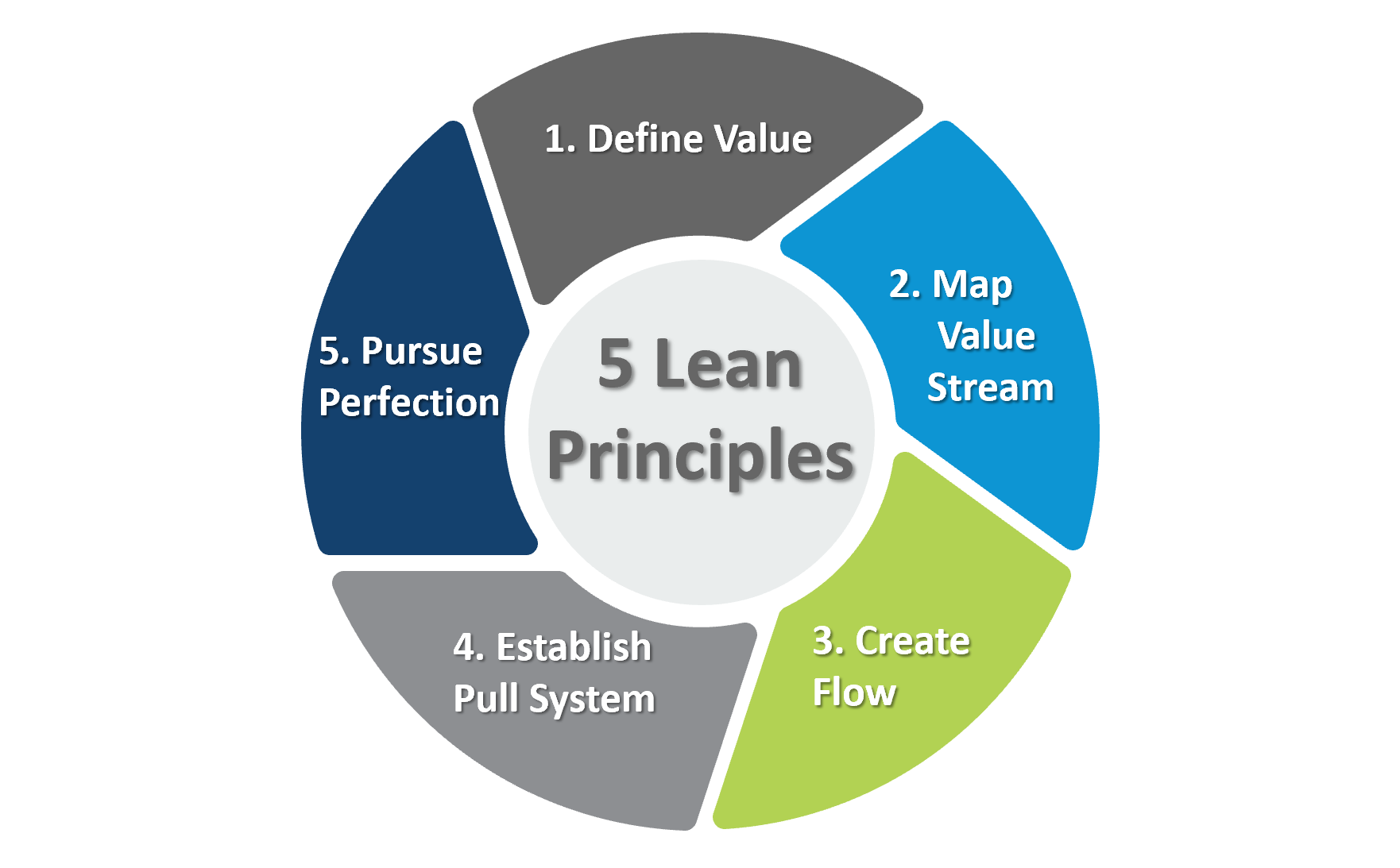

In the fast-paced world of electrical distribution, efficiency is paramount. Implementing Lean principles offers a powerful framework for optimizing operations, reducing waste, and ultimately, boosting profitability. While often associated with manufacturing, Lean’s core concepts are highly applicable to the distribution sector, providing a roadmap for streamlining processes and enhancing customer value. By embracing Lean, electrical distributors can transform their operations, creating a more agile and responsive organization. One of the foundational principles of Lean is the elimination of waste, or muda. In electrical distribution, this translates to identifying and eliminating inefficiencies in areas such as inventory management, warehouse operations, and order fulfillment. Overstocking, for example, ties up capital and increases storage costs, while inefficient picking and packing processes lead to delays and errors. By implementing techniques like 5S (Sort, Set in Order, Shine, Standardize, Sustain) in warehouse layouts and employing just-in-time inventory practices, distributors can minimize waste and improve overall efficiency. Value stream mapping is another critical Lean tool that can be used to visualize and analyze the flow of materials and information throughout the distribution process. By identifying bottlenecks and areas for improvement, distributors can streamline workflows and reduce lead times. This might involve optimizing delivery routes, implementing cross-training for employees to enhance flexibility, or leveraging technology to automate manual tasks. The goal is to create a seamless and efficient flow of goods, from supplier to customer, minimizing delays and maximizing value. Continuous improvement, or kaizen, is a fundamental aspect of Lean. This involves fostering a culture of ongoing improvement, where employees are empowered to identify and implement solutions to operational challenges. Regular team meetings, performance reviews, and employee feedback mechanisms can help to identify areas for improvement and drive positive change. By encouraging a culture of continuous improvement, distributors can ensure that Lean principles are embedded in their daily operations, leading to sustained efficiency gains. Finally, focusing on customer value is at the heart of Lean. By understanding customer needs and expectations, distributors can tailor their operations to deliver exceptional service. This might involve offering customized solutions, providing faster delivery times, or improving communication and responsiveness. By aligning operations with customer value, distributors can build stronger relationships, increase customer loyalty, and ultimately, achieve a competitive advantage. Implementing Lean principles in electrical distribution operations is not just about cutting costs; it’s about creating a more efficient, responsive, and customer-centric organization.

Implementing Lean Principles in Electrical Distribution Operations

Implementing Lean principles in electrical distribution optimizes operations by eliminating waste, streamlining processes, fostering continuous improvement, and focusing on customer value.