Providing energy-efficient solutions involves understanding customer needs, educating them on benefits, staying updated on technology, offering incentives, and providing ongoing support.

Preventing electrical downtime in manufacturing requires proactive measures like preventative maintenance, robust system design, monitoring, rapid response planning, power quality solutions, and a strong safety culture.

Troubleshooting common electrical problems in industrial settings requires a systematic approach to diagnose and resolve issues like voltage drops, tripped breakers, motor control problems, ground faults, and power quality issues, ensuring minimal downtime.

Industrial relays offer benefits like isolation, flexibility, reliability, enhanced safety, and cost-effectiveness for controlling and switching electrical circuits in industrial settings.

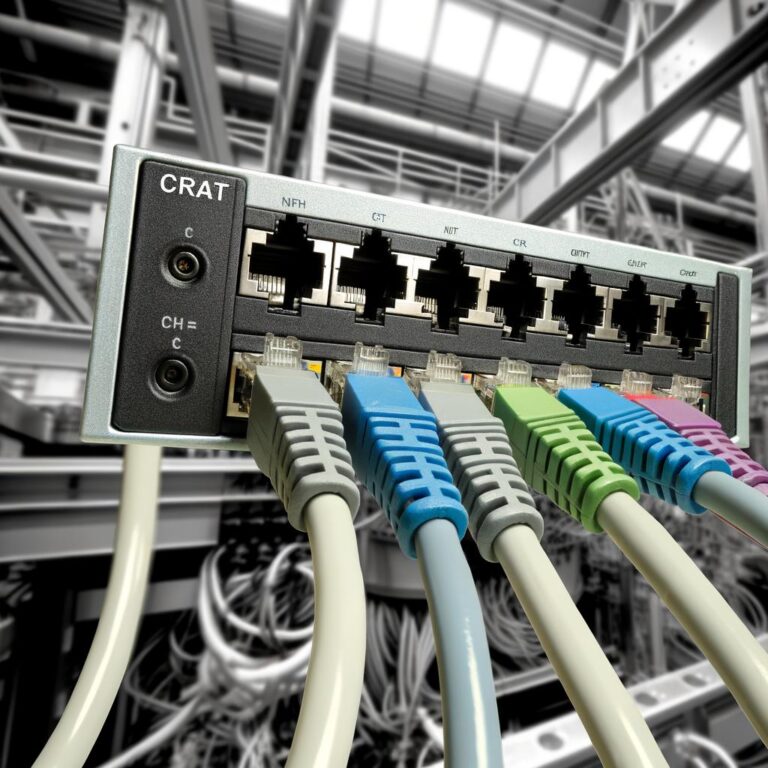

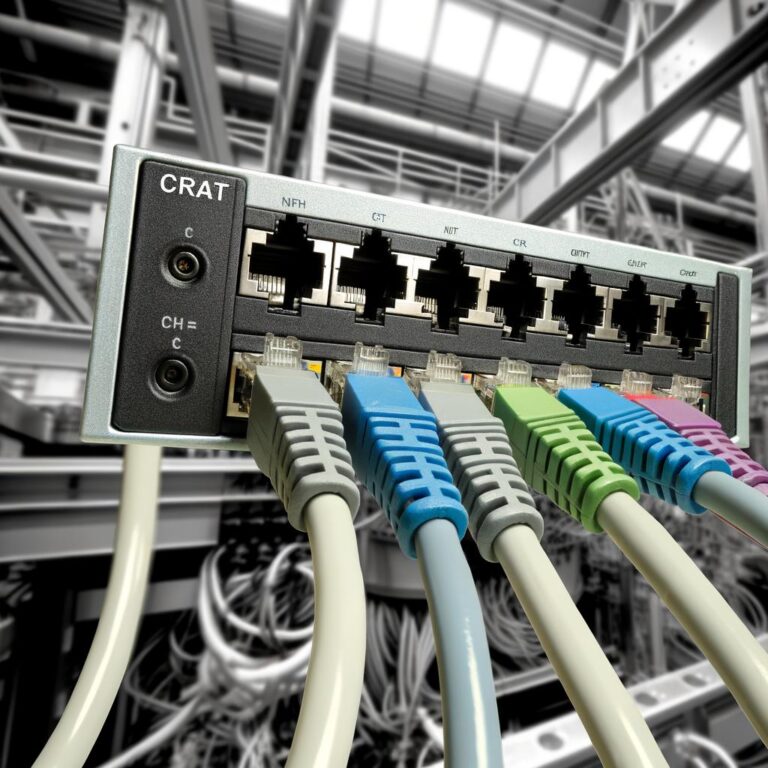

Ethernet switches in industrial settings enhance communication, reliability, security, and management through deterministic communication, redundancy, advanced security features, and remote monitoring capabilities.

Choosing the right generator involves assessing power needs, considering application and portability, selecting the appropriate fuel type, and evaluating features and specifications to ensure reliable power backup.

Energy monitoring systems provide real-time data and analytics to optimize energy consumption, reduce costs, and promote sustainability.

Selecting and installing industrial connectors requires careful consideration of application requirements, connector type, contact materials, proper installation techniques, thorough testing, and ongoing maintenance to ensure reliable connections.

Choosing the right transformer involves carefully matching voltage and power requirements, considering the application environment, frequency, winding type, and necessary features and certifications for safe and efficient power conversion.

PLCs offer industries flexible, reliable, and cost-effective automation through programmability, durability, diagnostic capabilities, system integration, and reduced downtime.